Wings of Silence

Records tell the truth about the Japan Airlines Flight 123 crash

Chapter 3: Void investigation report - 2

I'm Takahiro Jikusen, an aviation history researcher.

"The truth of the Japan Airlines Flight 123 crash that the record tells" is the final episode of this Chapter 3 Part 2 of the 7th series. I think I was able to introduce the records such as flight timetables and B747 boarding records.

The Jikusen theory concluded that the starting point was the damage to the vertical stabilizer due to the metal fatigue fracture near the vertical stabilizer connection.

At time zero, immediately after the momentary outflow of air in the cabin, the air stopped or was almost suppressed, allowing passengers and crew to remain conscious until the end.

My failure analysis consists of two main parts.

The first is the cause analysis of the destruction of the vertical stabilizer.

The second is the analysis of the in-flight environment that people were able to maintain consciousness until the end.

In order to review the causes of the accident, here is a diagram of the causes of the accident. I called the three high conditions of SR aircraft, such as high in-flight pressurization, high flight altitude, and high frequency of flight.

The link diagram shows how the three highs and other factors led to the accident. It's a collection of factors I've talked about, but please stop the screen and take a look at it later.

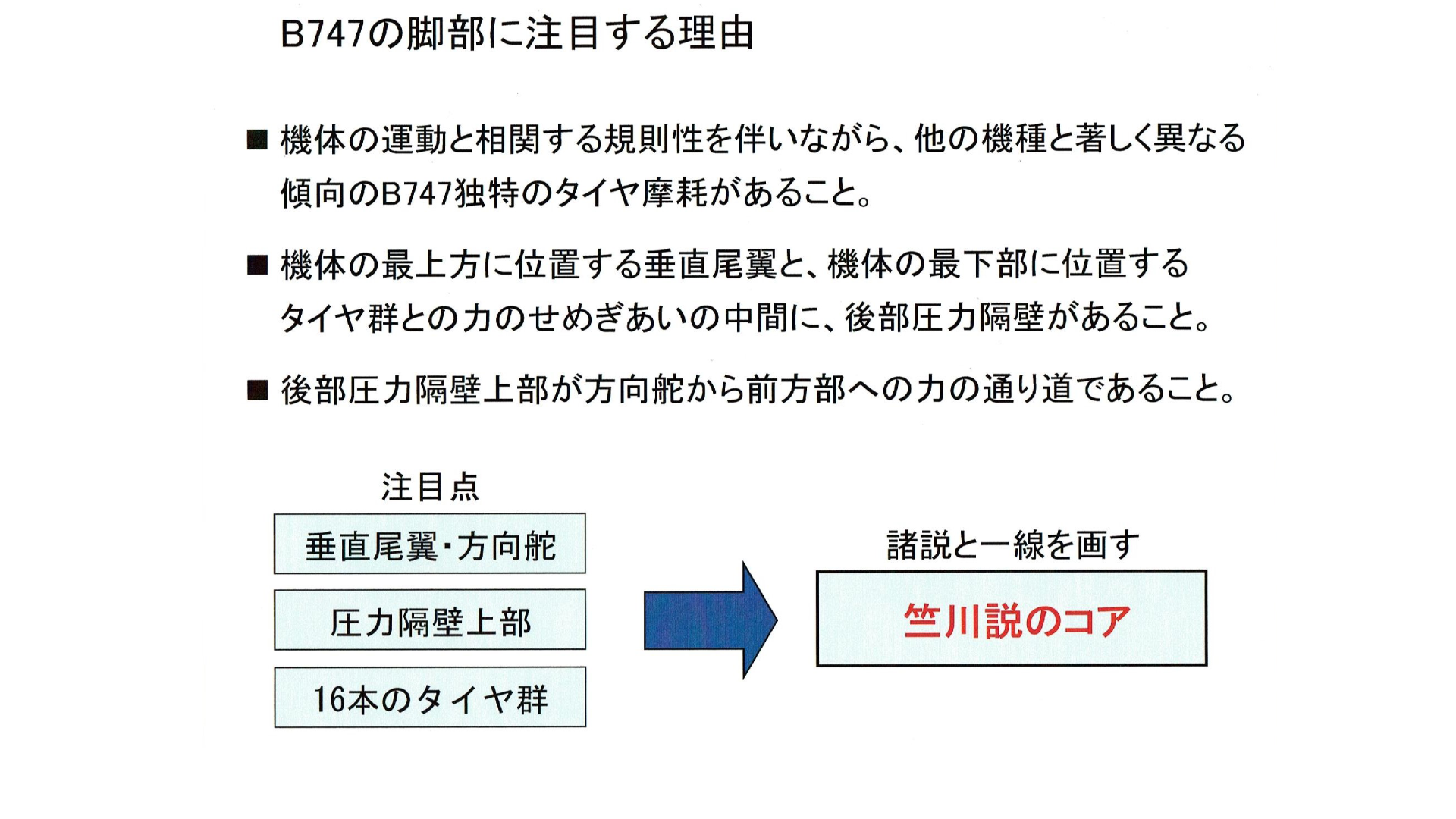

I would like to explain the causal relationship between the consequences of the B747 airplane's characteristics and failure, especially because the leg characteristics are an important factor.

First, let's look back on the history of the B747, but first I will introduce the appearance of passenger aircraft.

The first successful jet airliner on the market was the Boeing B707 shown here, and its rival DC-8 appeared about half a year later.

In 1969, the B747 was introduced in response to growing market demand. Here I focus on the legs.

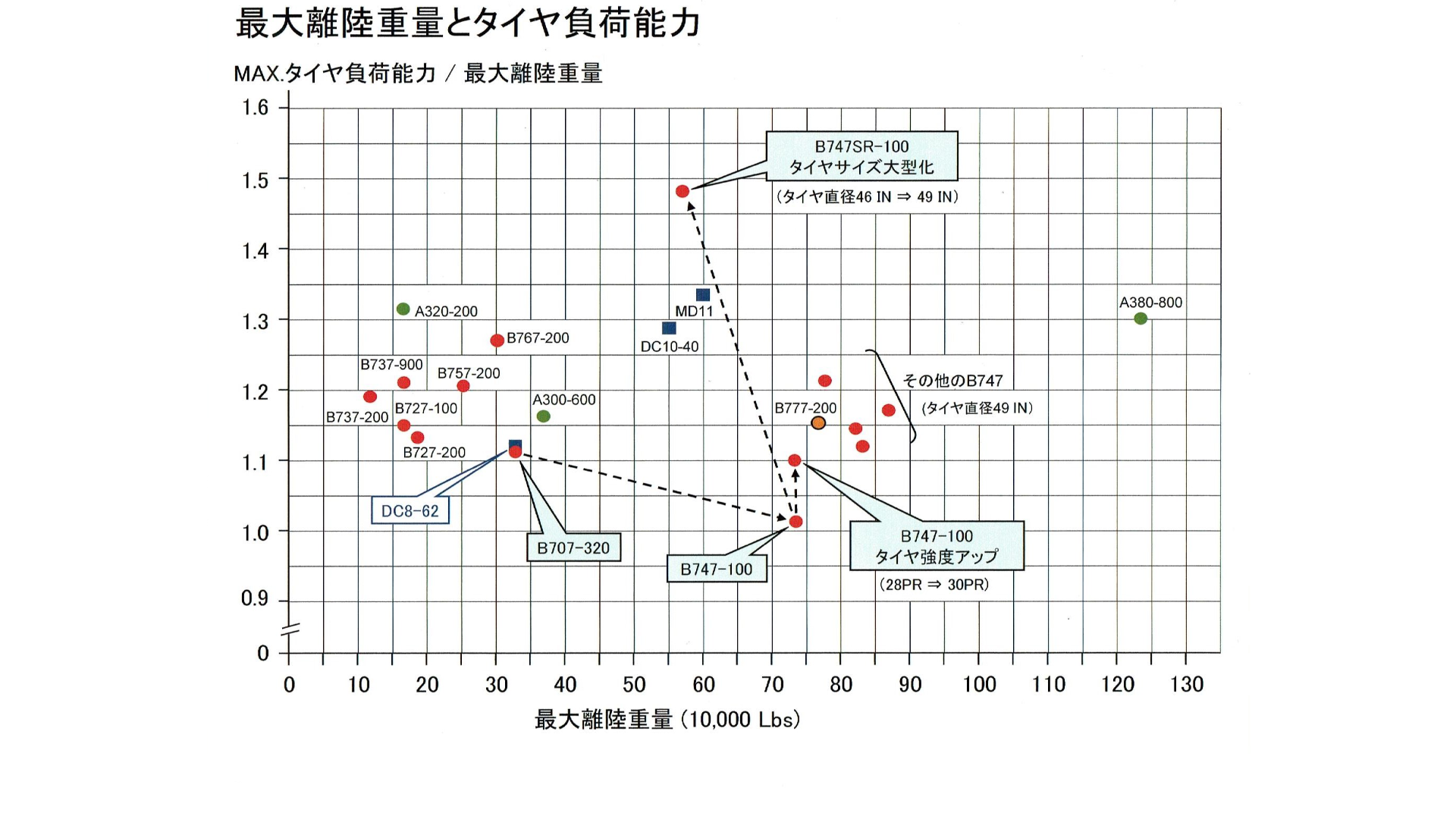

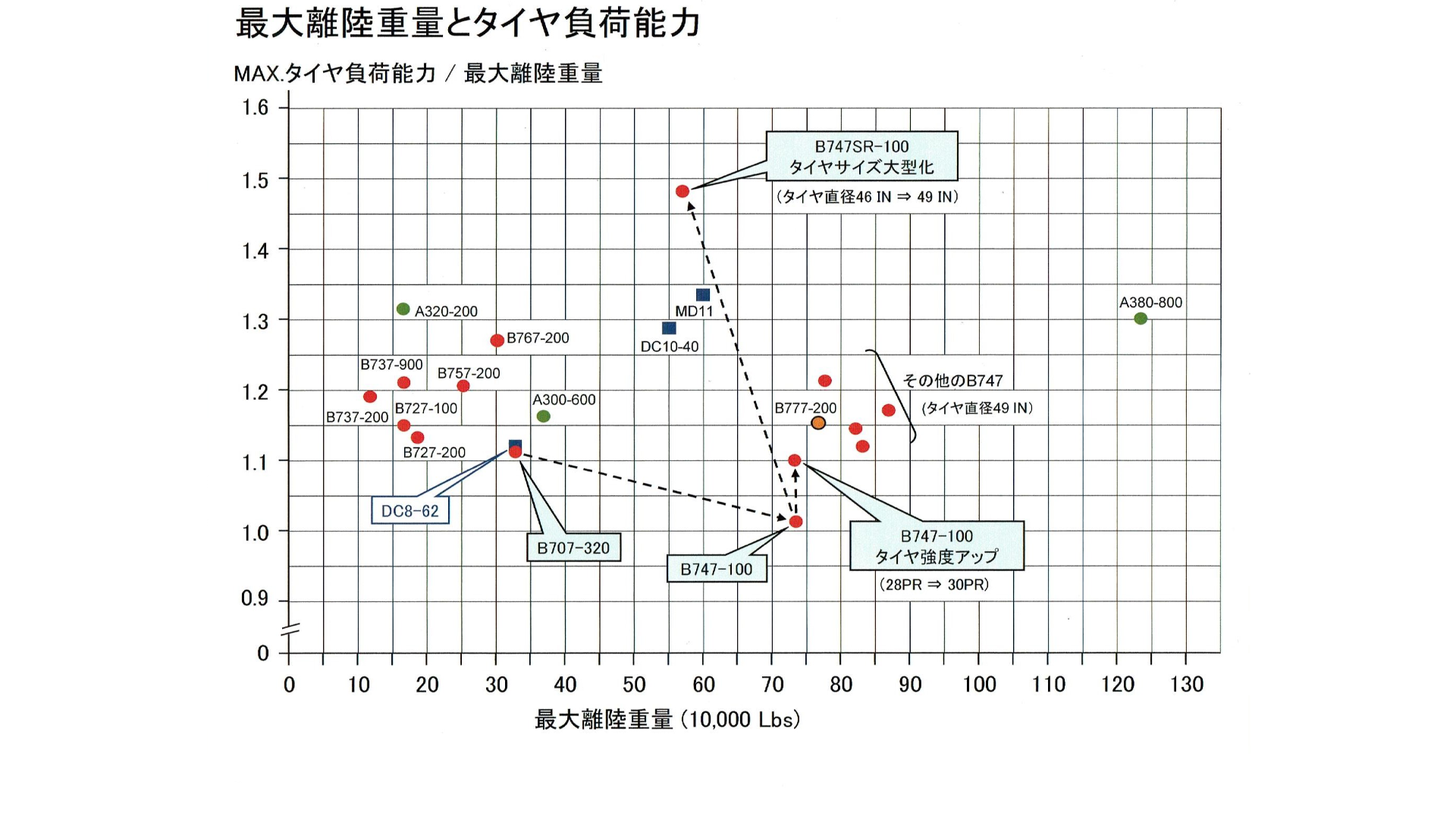

This figure shows the relationship between the maximum takeoff weight and the maximum load capacity of the tires to be mounted.

Joe Satter, the chief designer of the B747, considered the undercarriage with reference to the B707 when designing the legs of the B747. The point is to double the number of main wheels and distribute the load in consideration of the road surface strength.

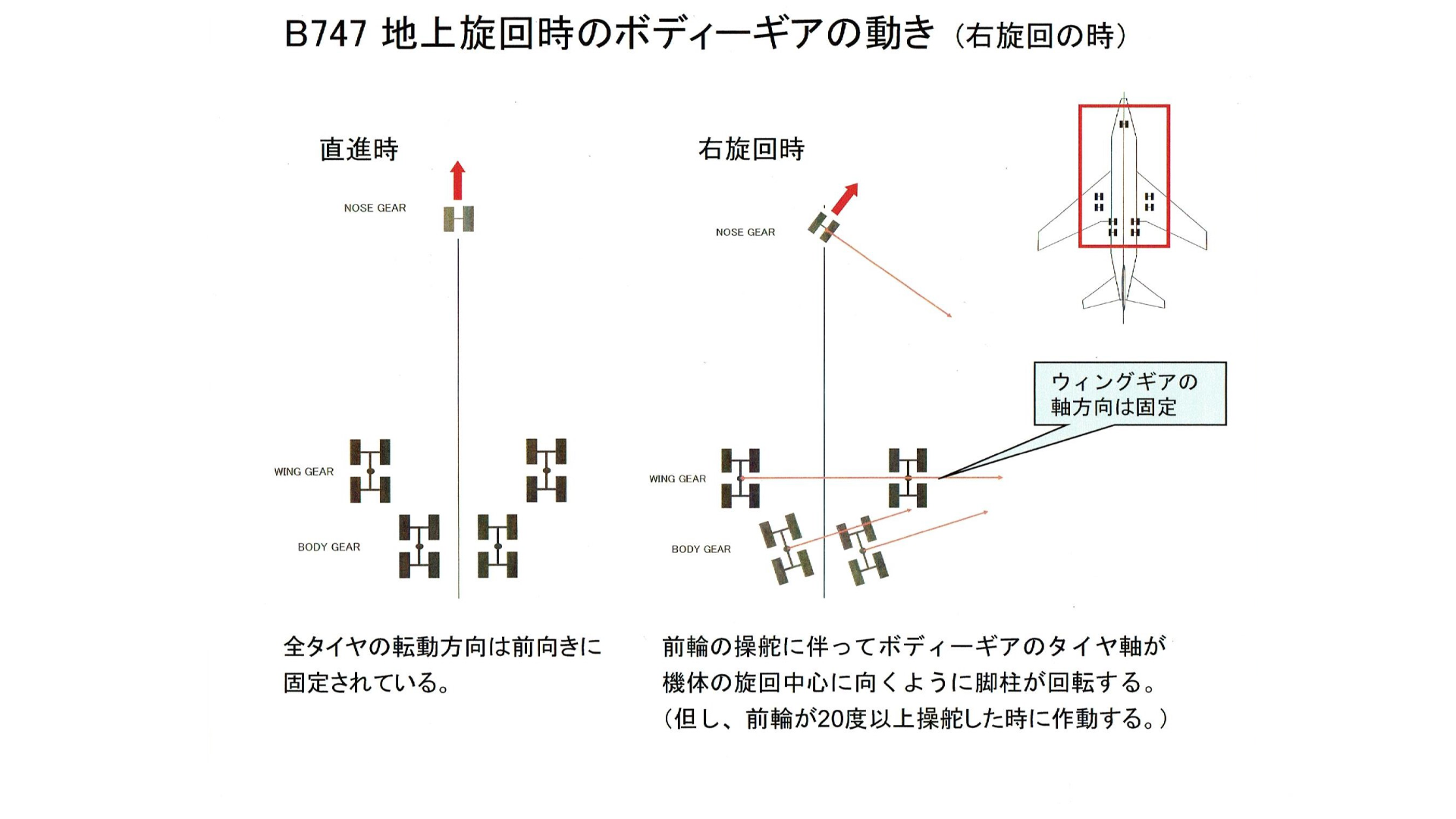

However, since it was expected that it would be difficult to turn on the ground, he decided to rotate the eight tires, which are called body gears, together with the pedestals as shown in the figure.

It turned out that this wasn't enough, and Joe Satter himself recalled that it should have improved. I think that the distribution of tires over this wide area was the cause of this accident.

The maximum takeoff weight of the B747-100 is almost double that of the 707, and the -100 was fitted with tires with the same specifications as the 707.

The 707 was at a level above 1.1, and this 10% margin suppressed tire failure. However, since the margin of -100 is as small as 1.0 as shown in the figure, tire failures occurred sporadically at the beginning of operation.

There were sporadic failures in which the tires burst during takeoff and lost load capacity in an instant.

Immediately after the time zero, the captain said, "Gear, look at the gear," but I think it reacted reflexively with the explosion sound = tire burst. I instinctively thought that the pilot who knew a long time ago immediately associated the tire burst with the explosion sound.

The next time the -200 came out, the weight of the aircraft increased, so the 49-inch diameter tires proven on the B727 were adopted. For about 50 years until the latest -400ER, Boeing has consistently used 49-inch diameter tires on the 747.

The SR aircraft was the third aircraft in the 747 series. The undercarriage followed -200, but the maximum takeoff weight was reduced, so the margin of tire load capacity increased to nearly 50% at once as shown in the figure.

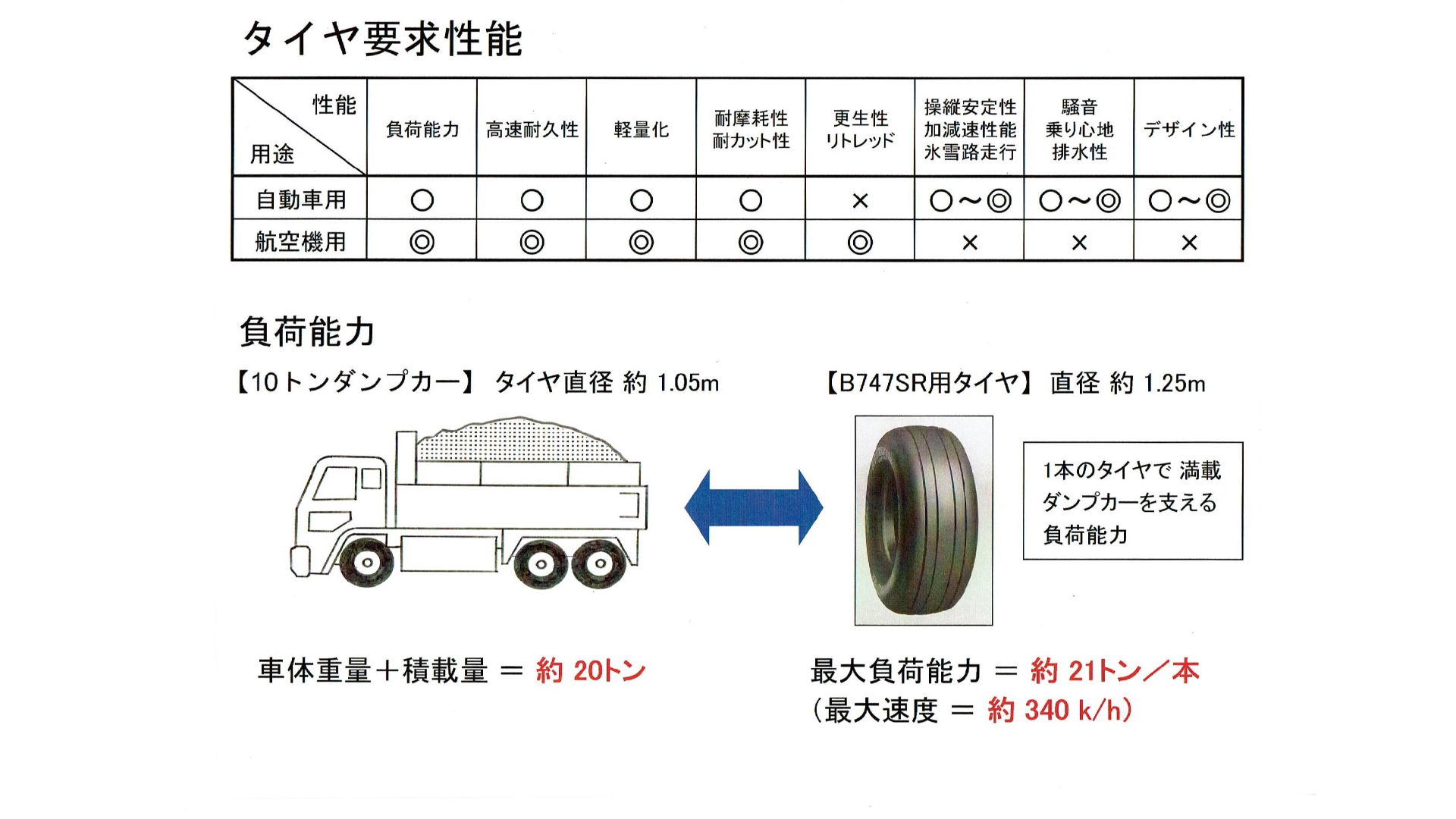

I think that it will be a reference for creating the image of the Jikusen theory, so I will compare the tires for automobiles with those for aircraft.

This figure shows an example of an airplane tire carrying a large load. When the 10-ton dump truck is fully loaded, it is almost the same as the maximum load of one tire mounted on the B747SR. You may be surprised by this fact.

Actually, the maximum load that the tire bears when mounted on the SR aircraft is about 15 tons because the margin is large, but it is still a large load.

Aircraft tires are designed to maximize their performance by narrowing down their performance characteristics. Noise and ride quality are not considered in the design at all. Steering stability and acceleration / deceleration performance are the roles of the aircraft itself.

Airctaft tires are one of the most useful parts on the ground, but as soon as they take off, they transform into weights, so tires are always required to be lighter.

The biggest reason why tires are removed is that they are cut by stepping on foreign objects, so tires that are strong against cutting are required.

Unique is the retread. In general, worn tires of commercial airliners are usually retreaded by re-covering the surface 5 to 6 times, so the tires are also required to have durability that allows them to be retreaded.

Aircraft tires have the highest performance in a load- and speed-specific manner. However, it will be the performance that can be exhibited within the range of the runway length.

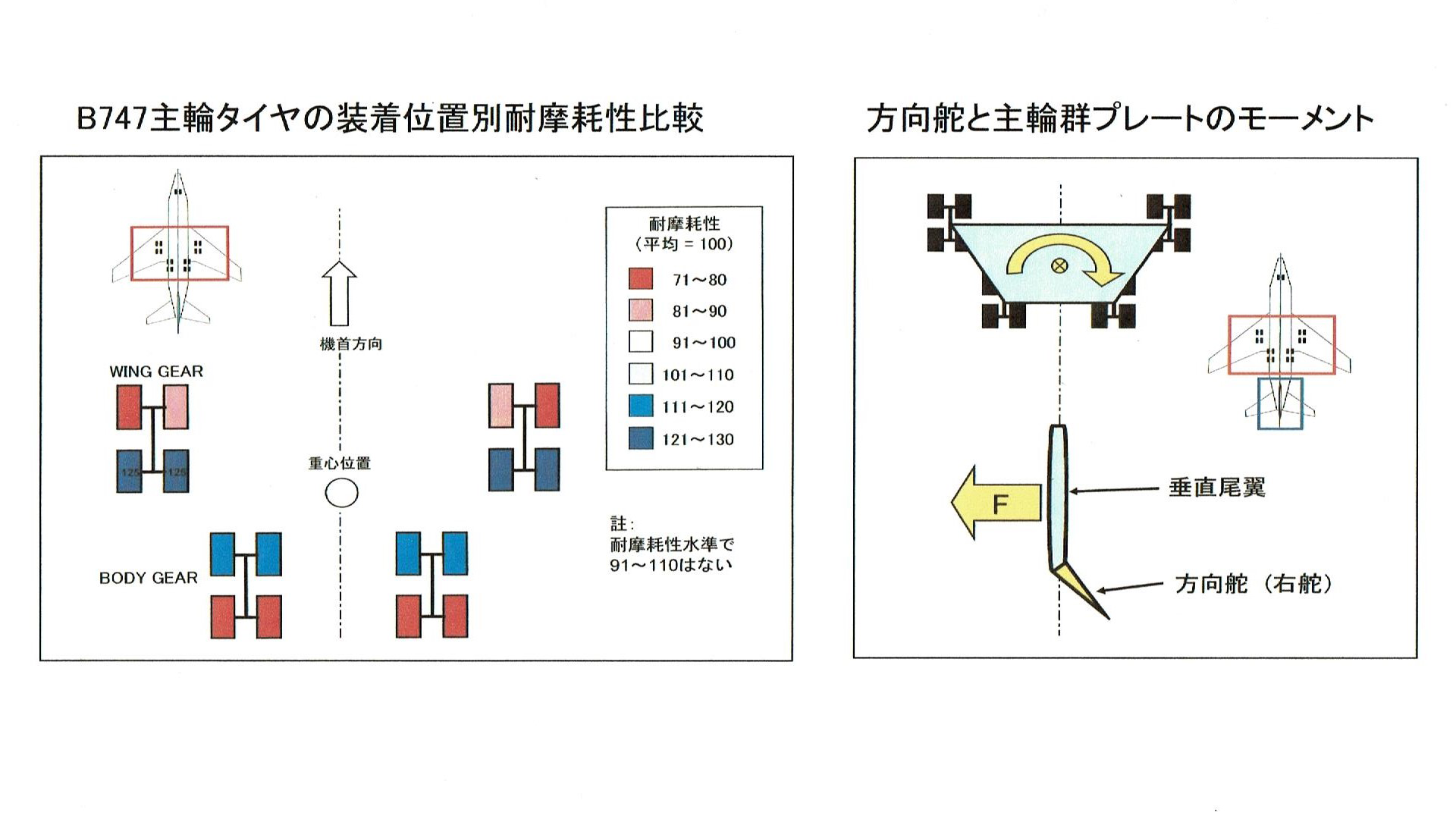

Since the 16 main wheel tires are directed to drive straight together, the main wheel tires will be forced to skid when the nose direction changes. Therefore, the B747 has a big difference from other aircraft in that a significant wear difference occurs depending on the mounting position of the tire.

As for the actual wear level, when the average wear degree of 16 main wheels is 100, there is a wear difference of 75 to 125 levels between the 16 tires. The red position wears quickly and the blue position tires last longer.

By the way, B737 and A320 with one main axle wheel fall in the range of 95 to 105 level.

The figure on the right shows four tires loaded at the four corners of the trapezoid fixed forward. The figure below shows the vertical stabilizer and the rudder with the right rudder turned.

If it were to rotate clockwise around the center of gravity of this trapezoid, the left-handed force F obtained from the right rudder would need to be considerably large, and the rudder would be damaged under static conditions on the ground. I think it will be.

The only force that an airplane shakes during high-speed gliding is the aerodynamic F generated from the rudder. When the aircraft is moving, the coefficient of friction becomes significantly lower, so it is possible to change direction with the force generated by the rudder.

However, there is a difference in the slip of each tire depending on the mounting position during rolling, and the result is reflected in the difference in tire life.

I focused on the rudder force and the moment that rotates the trapezoid.

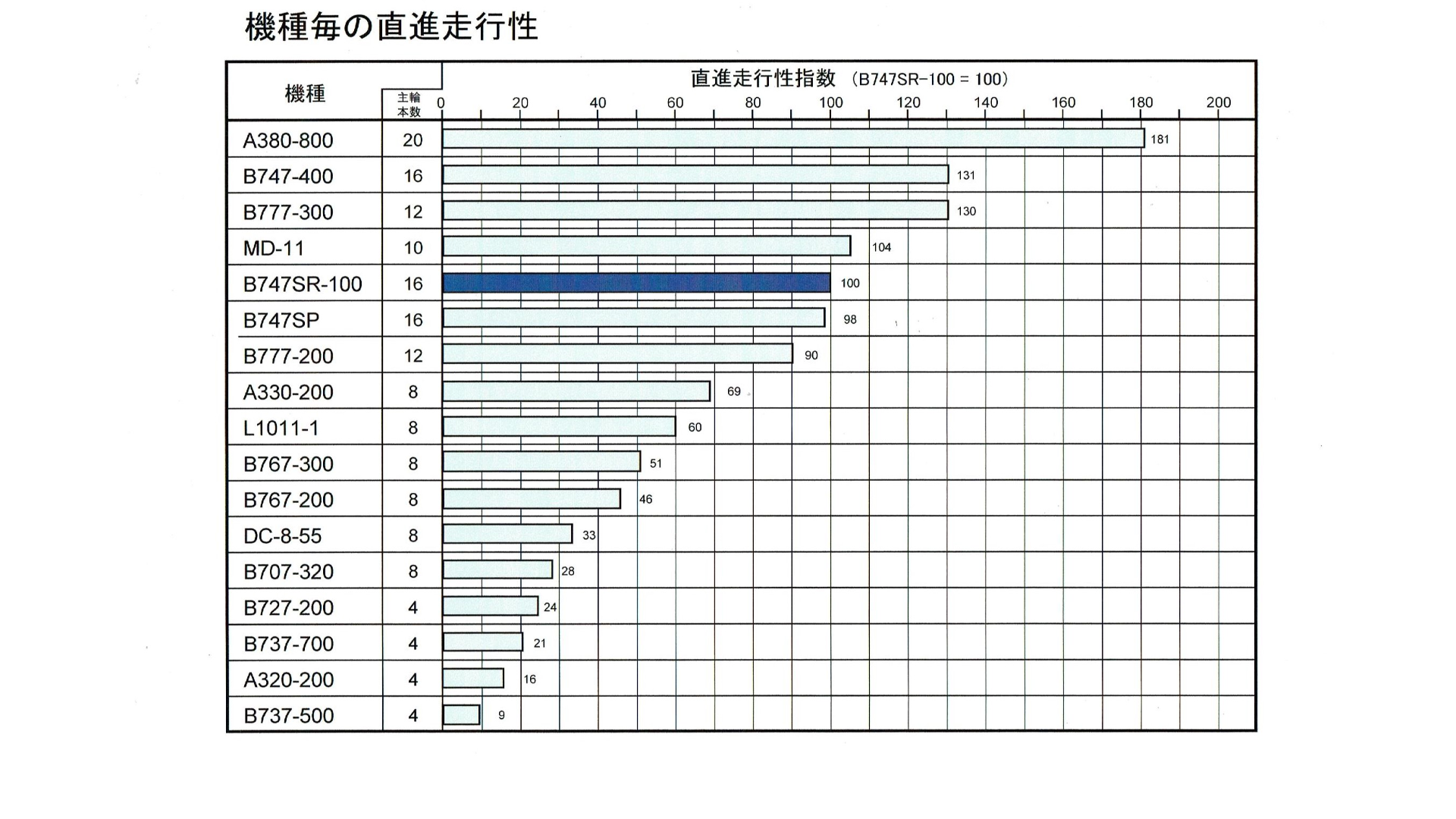

This figure is a diagram of "straight running performance for each model" introduced in Chapter 1.. The B747SR has the highest index among short-range aircraft with many takeoffs and landings.

I came to think that there is no reason why the peripheral part of the pressure bulkhead in the middle of the force transmission path starting from the rudder that produces the force to change the nose direction can not be affected.

I noticed that a torsional moment is always generated at the base of the cantilever vertical stabilizer every time the rudder is moved.

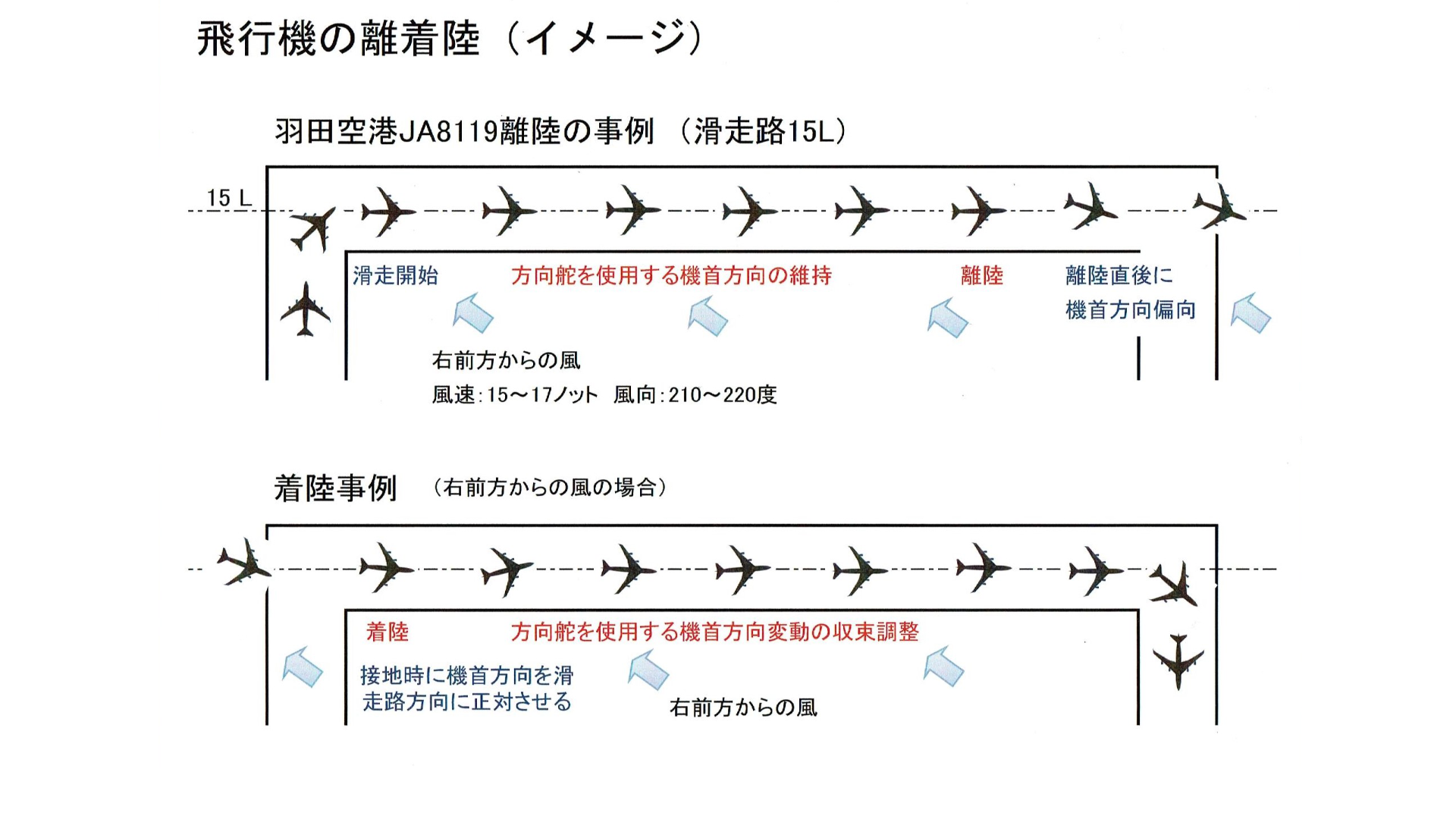

This figure shows the situation of takeoff and landing at the time of right crosswind, the upper part is taking off and the lower part is landing.

Since the front wheels and 16 main wheels are all fixed forward on the runway, the tires slip sideways each time the crosswind is adjusted when the aircraft is swept by crosswinds, the tires are forced to skid each time the nose is adjusted to face the front.

At the time of landing, the nose direction is approached upwind from the beginning, and the basic maneuver is to face the runway just before touchdown. Swing the rudder left and right during the run to converge the direction toward the runway.

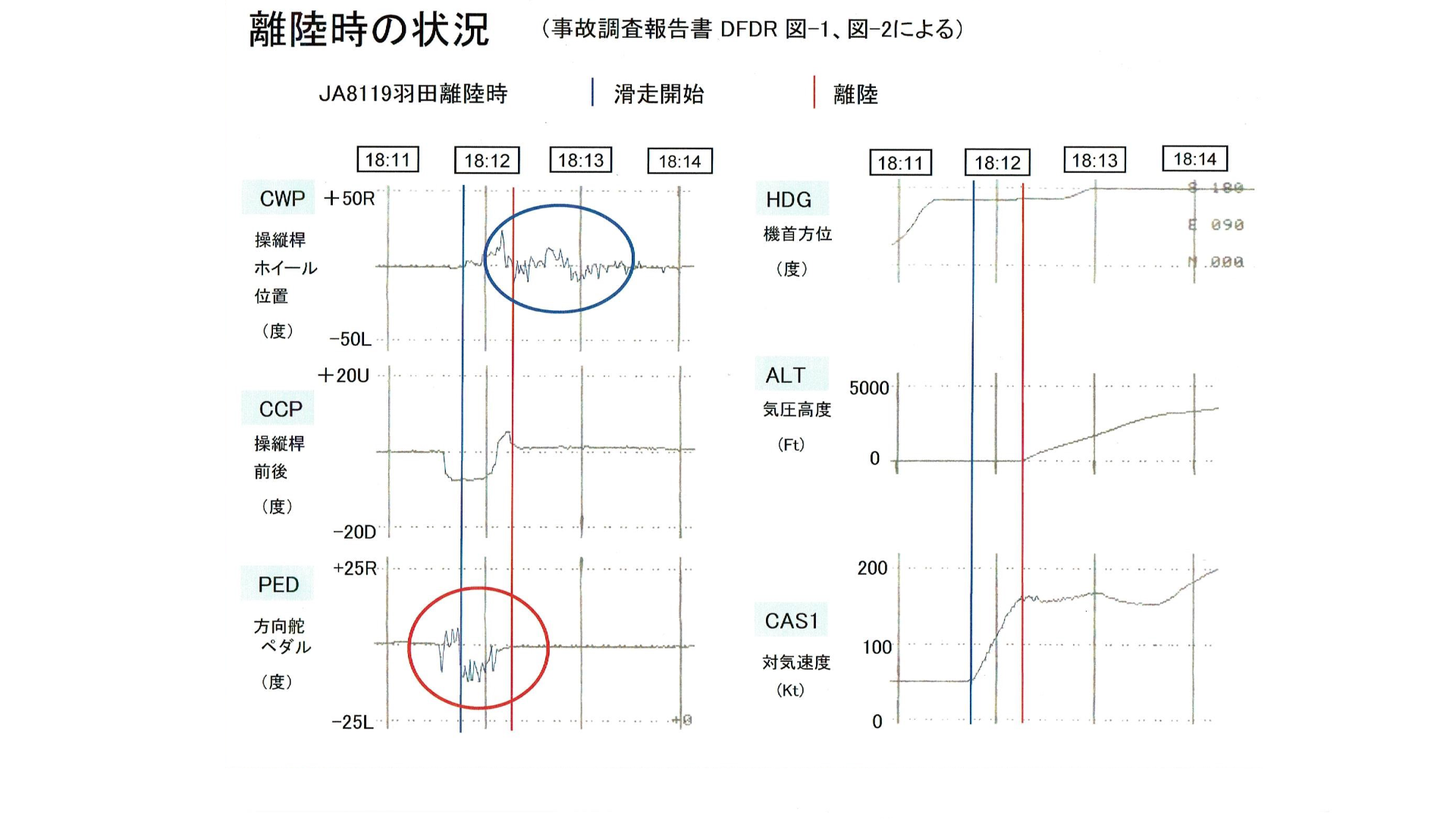

I will consider the state of steering during high-speed gliding from the flight recorder data at the time of takeoff of JA8119.

The data show about 3 minutes before and after taking off from Haneda.

Attention is focused on adjusting the rudder direction to the runway direction by frequently operating the rudder while traveling on the ground until the moment of takeoff, as circled in red.

To maintain the direction from just before takeoff, the control stick is operated left and right as shown by the blue circle.

Since the nose faces to the right as it is, the left pedal was depressed many times as surrounded by a red circle, and the nose direction was adjusted by operating the rudder.

As mentioned in Chapter 1, it is estimated that JA8119 would have reached about 1 million times since the start of operation.

I speculated that the force to correct the nose direction, that is, the force generated by the rudder, would have to be stronger due to the unbalanced tire wear of the B747 compared to other models.

The force exerted near the pressure bulkhead located at the base of the vertical stabilizer cannot be ignored.

Each time the rudder is steered, the vertical stabilizer collapses and fatigue accumulates near the fuselage connection.

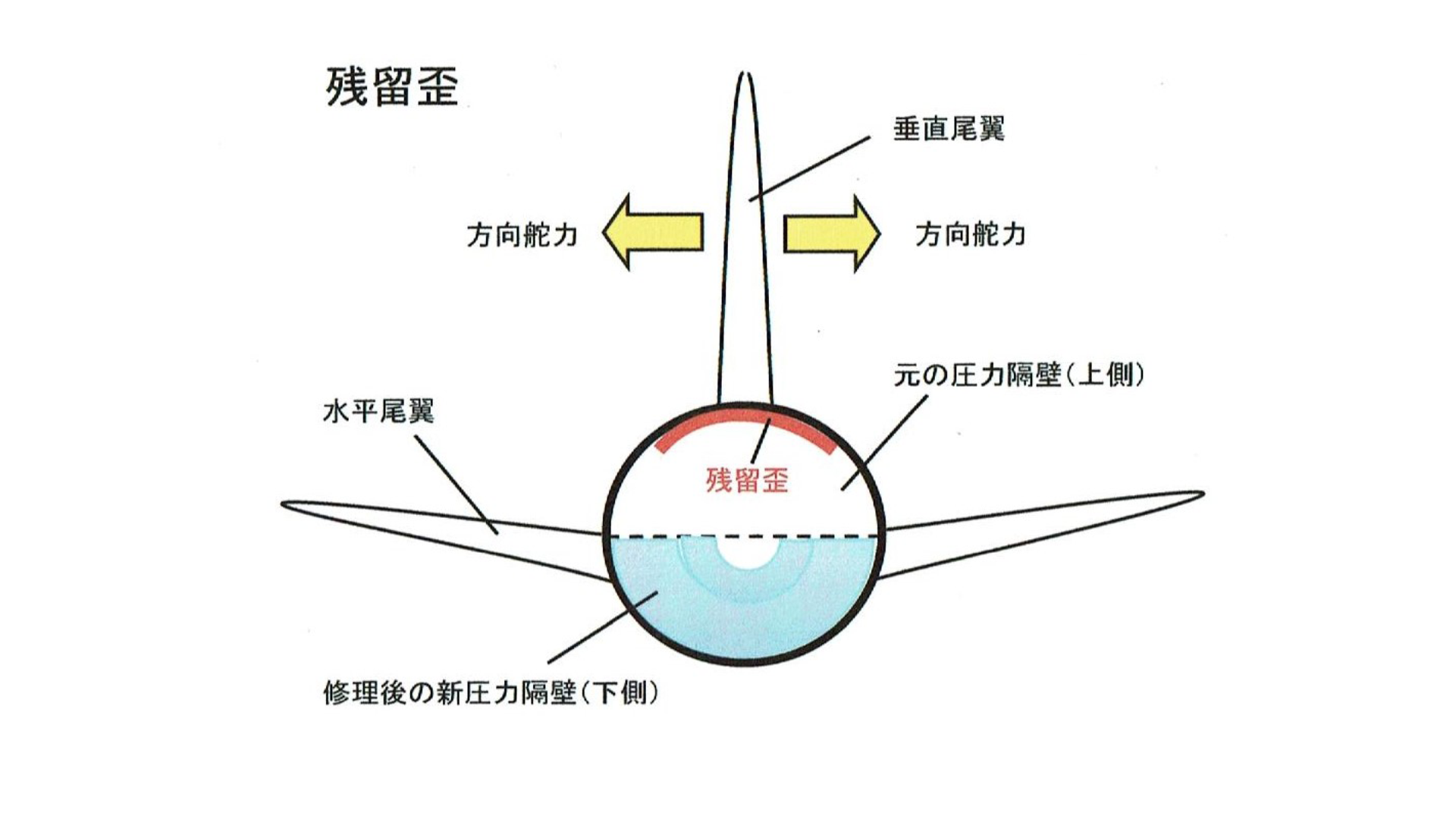

I think it is a repair mistake that the strain remained near the pressure bulkhead, that is, that Boeing did not replace all the pressure bulkheads.

And it was the leg structure that inevitably skid the main wheel tires peculiar to the B747 that developed the distortion into a failure. The B747 requires a powerful rudder force.

So far I have considered the force when traveling on the ground, but after takeoff I have to consider the strain due to the expansion and contraction of the fuselage.

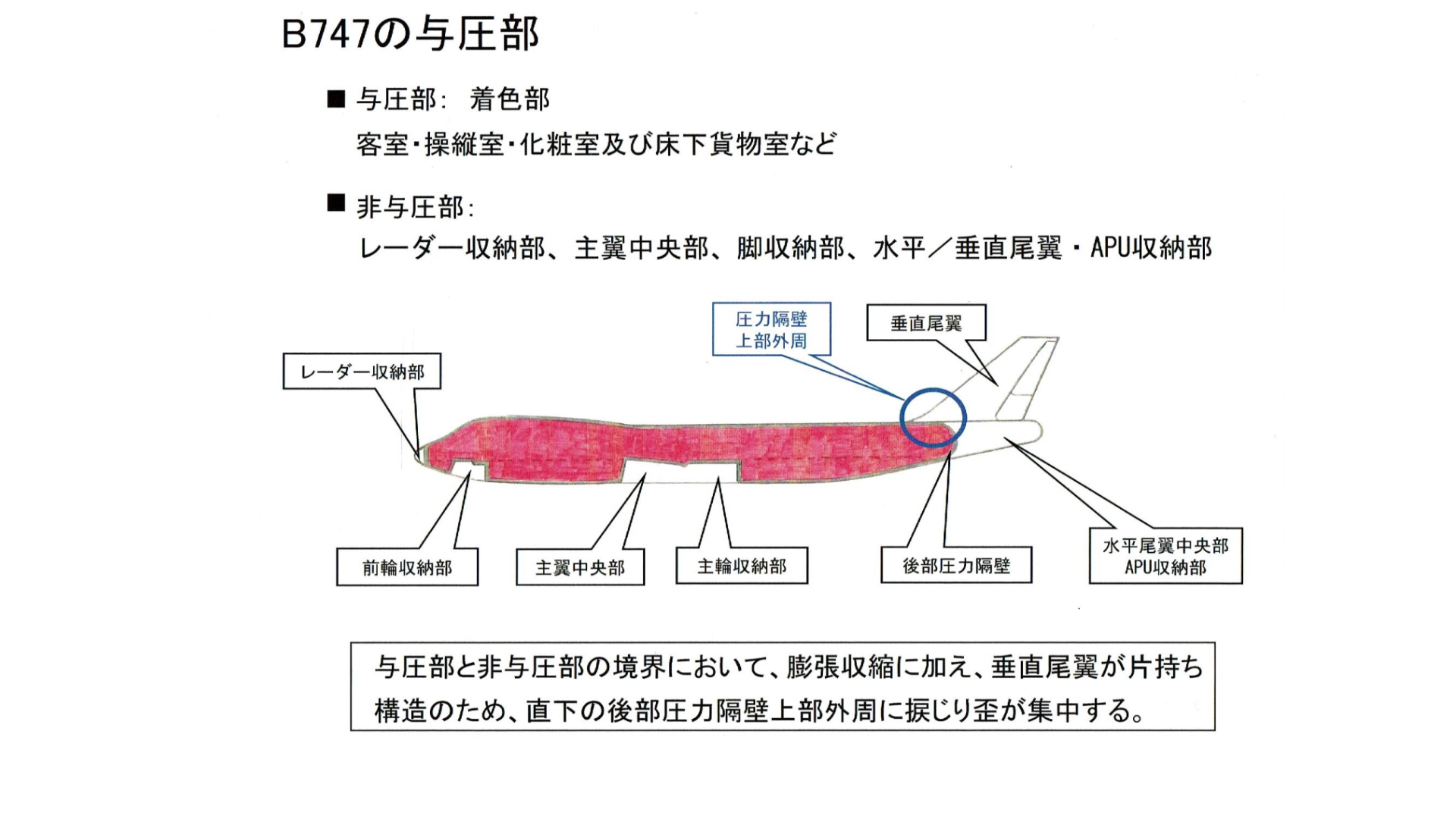

The figure shows the pressurized part of the B747 colored.

If the pressurized part is a pressure vessel, the strain will be concentrated at the joint part with the pressure bulkhead. As shown in the figure, pressure bulkheads are located on the wall surface of the tire hangar, the wall surface of the radar storage section.

The pressure bulkhead just below the vertical stabilizer is special. This is because all of the force that changes the nose direction is transmitted to the front of the aircraft via the area around the upper part of the pressure bulkhead.

It can be seen that the upper part of the rear pressure bulkhead with the vertical stabilizer of the cantilever structure is accompanied by twisting.

I have basically considered events before time zero, but there is a correction first.

Last time, in Chapter 3, Part 1, I mentioned that the date of time zero was August 15, but the date of the accident is August 12. I made a mistake. I will correct it. We would like to thank the viewers for pointing this out.

Finally, I would like to make three impressions throughout.

The reason I am so obsessed with the causal relationship between the B747's leg structure and the accident is that it involves the problems that the aircraft designer wanted to solve.

I noticed a unique tire wear feature that is significantly different from other aircraft, with regularity that correlates with the movement of the aircraft.

The wear data of more than 1000 tires I have seen speaks for itself.

There was a rear pressure bulkhead between the vertical stabilizer located above the fuselage and the tires at the bottom of the fuselage.

Focusing on the connection of the pressure bulkhead, I was convinced of the failure process drawn using the marble principle. I noticed that the air leak was self-blocking due to its shape.

Regarding the transmission of force and the movement of air, this became the core of the Jikusen theory, which sets it apart from various theories.

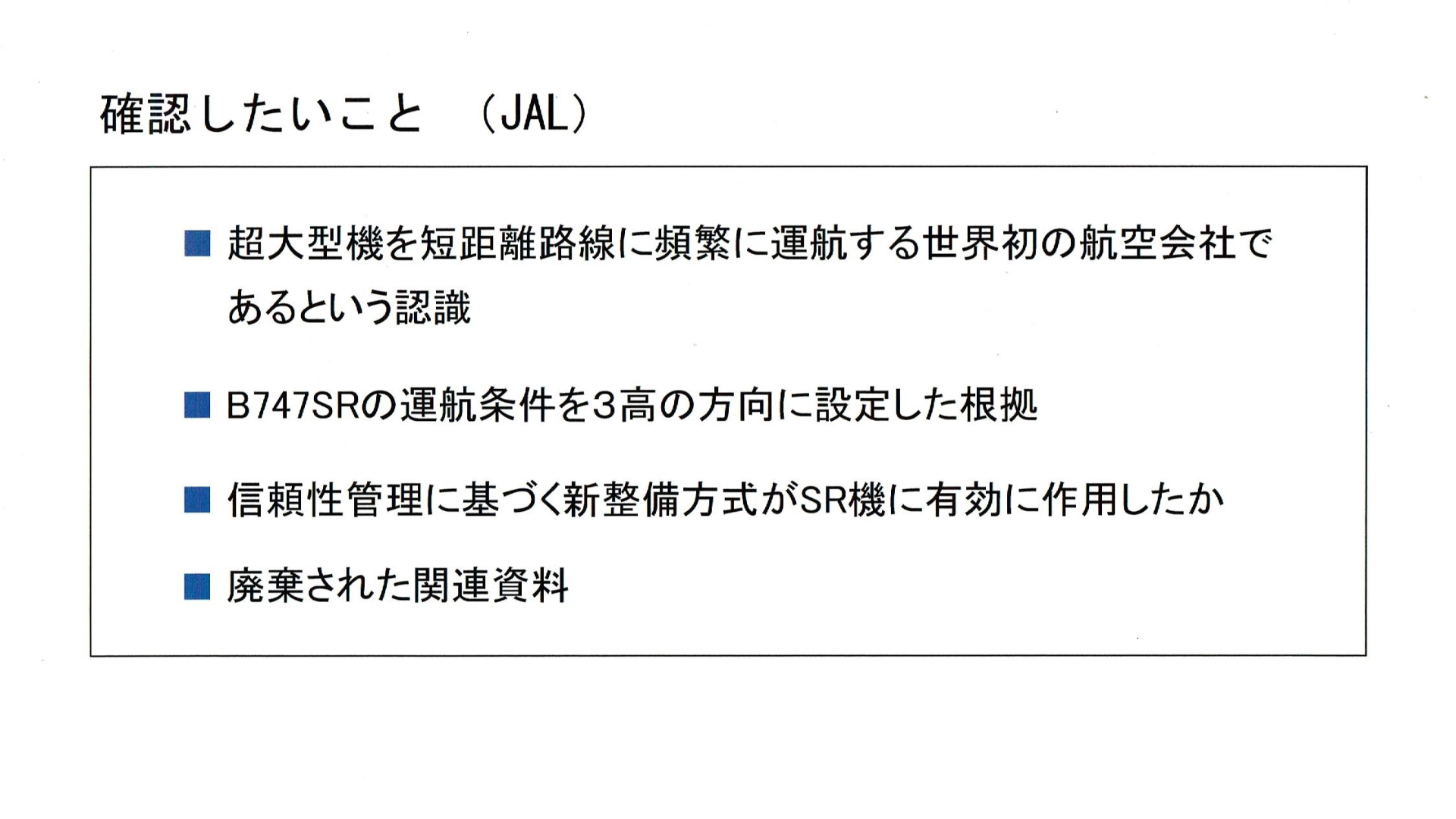

The second impression is about JAL.

The impression I got from writing the series is JAL's lack of awareness that it is the world's first airline that frequently operates ultra-large aircraft on short-haul routes. And there is a lack of caution when setting the operating conditions of the B747SR to 3 high.

How did the maintenance method based on reliability management, which should follow this, affect the SR aircraft?

The 1980s were praised as Japan as No.1. JAL became the world's number one in air transportation in 1984. It would be a real shame if the positive behavior was praised, but the cautiousness was neglected.

On the other hand, the airlines involved do not speak silently, but what was the purpose of disposing of a ton of materials?

The third impression is that I was reminded that the cause is lurking in the familiar scenery.

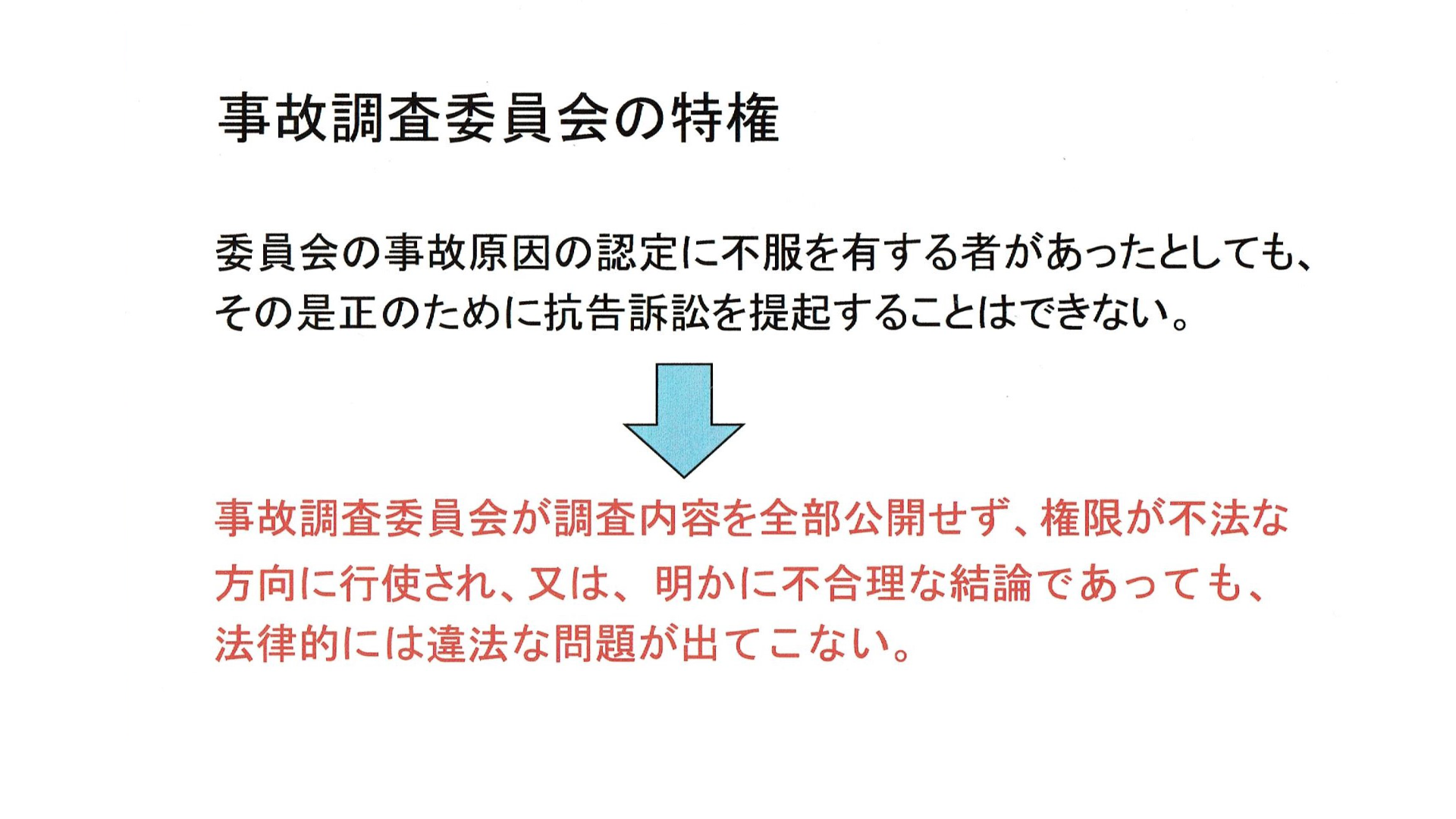

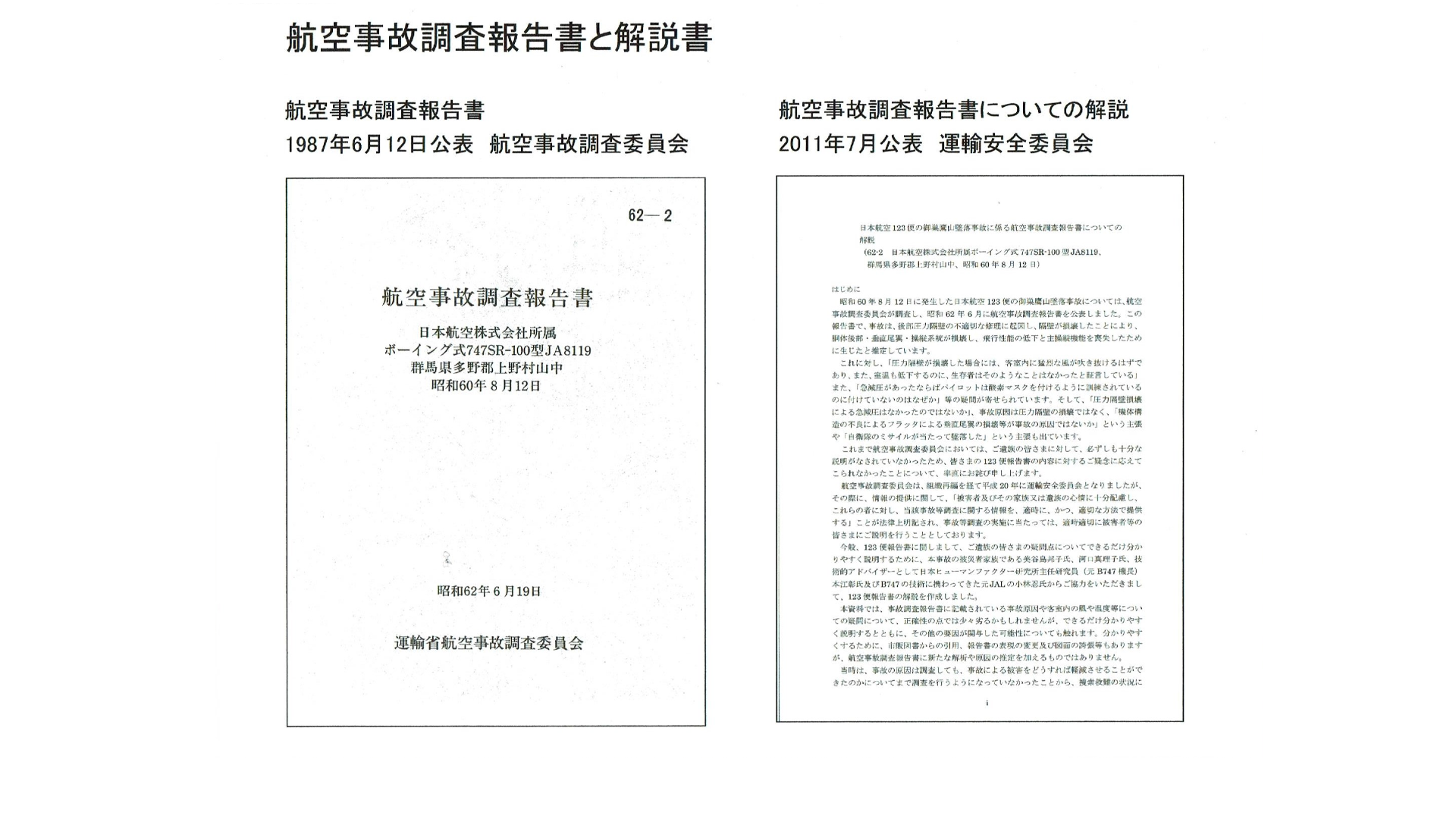

Regarding the accident investigation report itself, the accident investigation committee made a mistake in accepting the cause theory on the US side at the beginning, and the situation was far from being settled, and the doubts deepened and it still does not go away.

I have the impression that the Accident Investigation Commission was entrusted with troublesome things by the US side and was tasked with ending irrational things as if they were rational things.

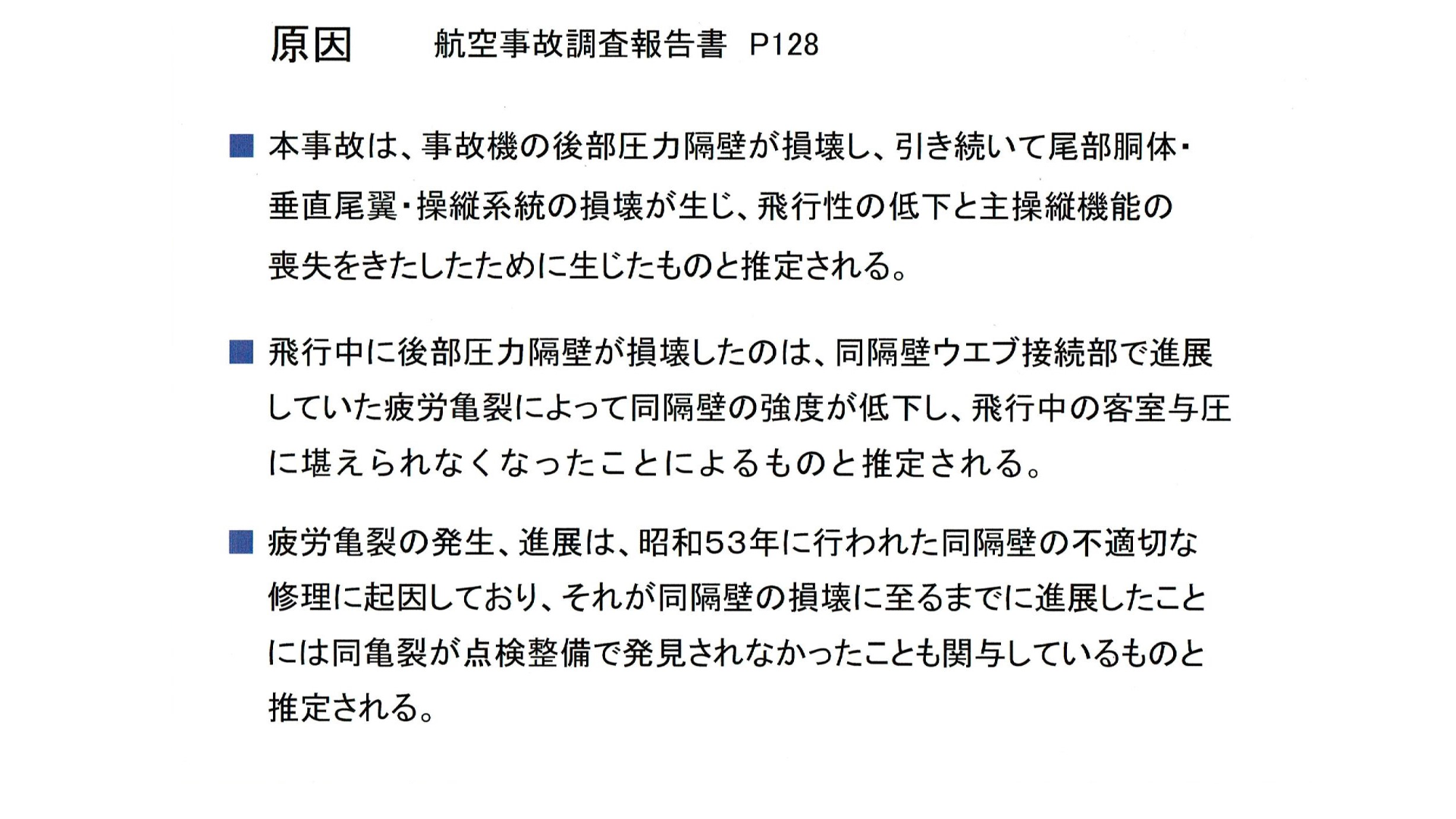

Let's take a look at the full text of the cause announced by the Accident Investigation Commission.

As I mentioned in my series, the published content cannot explain the actual situation and causes contradictions.

The accident investigation report remains locked up in the labyrinth and does not move. This is exactly what the "Void Accident Investigation Report" looks like.

The Japan Transport Safety Board does not leave it to the passage of time and seems to be patient. Will the report continue its absolute policy, relying on the backing of the law?

The contents of the "Explanatory Manual" issued 26 years after the accident do not show the strength of the accident investigation. I think that sufficient conditions should be met to claim the cause.

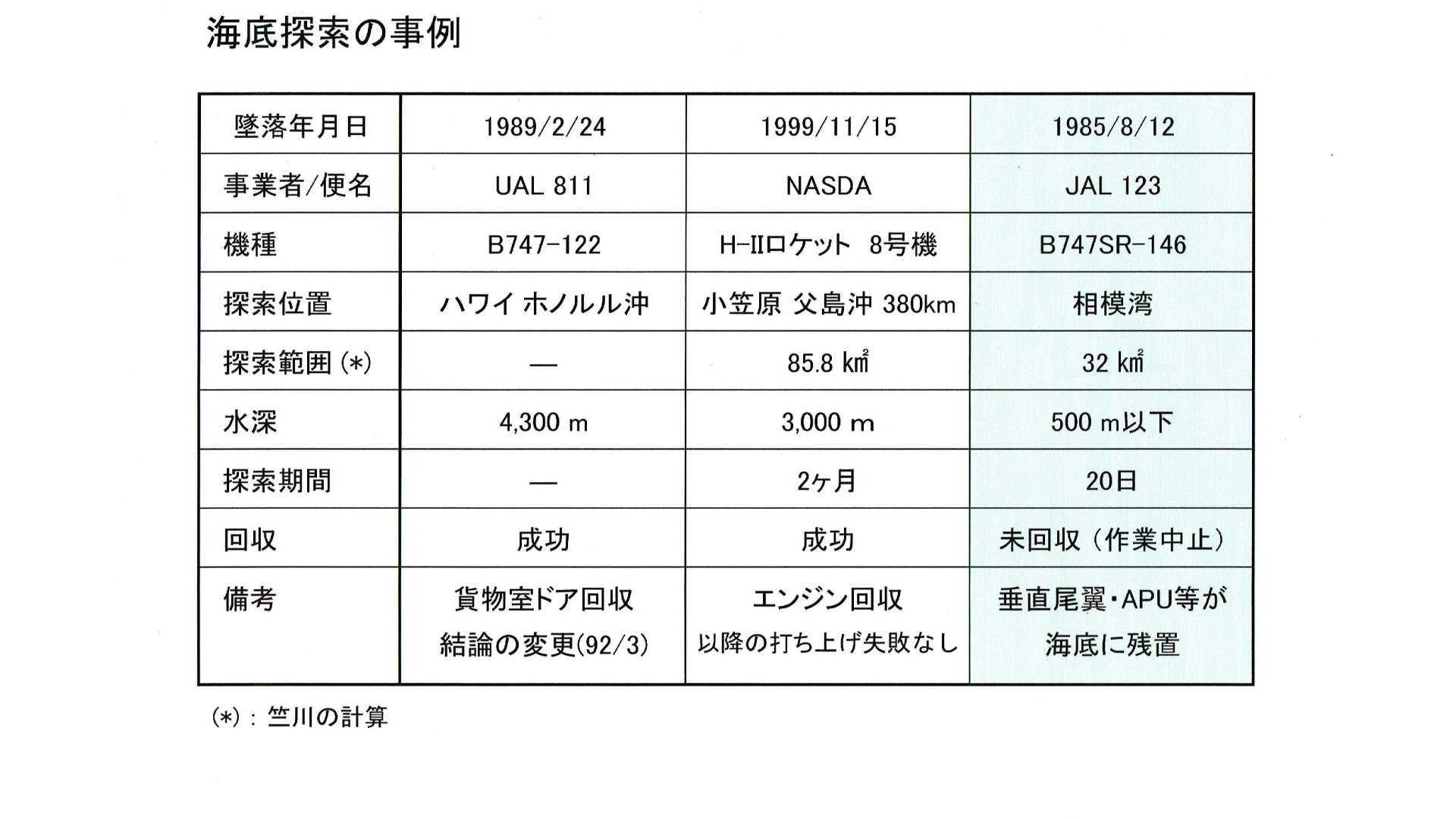

For example, the Commission should pull up the wreckage of the vertical stabilizer that sinks into Sagami Bay and make sure that a significant amount of insulation is infused inside.

It can be done without difficulty with the current technology, but is it possible?

In the United States, in February 1989, the wreckage of a crashed B747 was pulled up from the seabed, and as a result of a re-investigation, the original conclusion was overturned.

In Japan, the H-II rocket No. 8 that fell due to an engine failure was recovered from the seabed of 3000 m in November 1999, and the reliability after the cause has been clarified is remarkable.

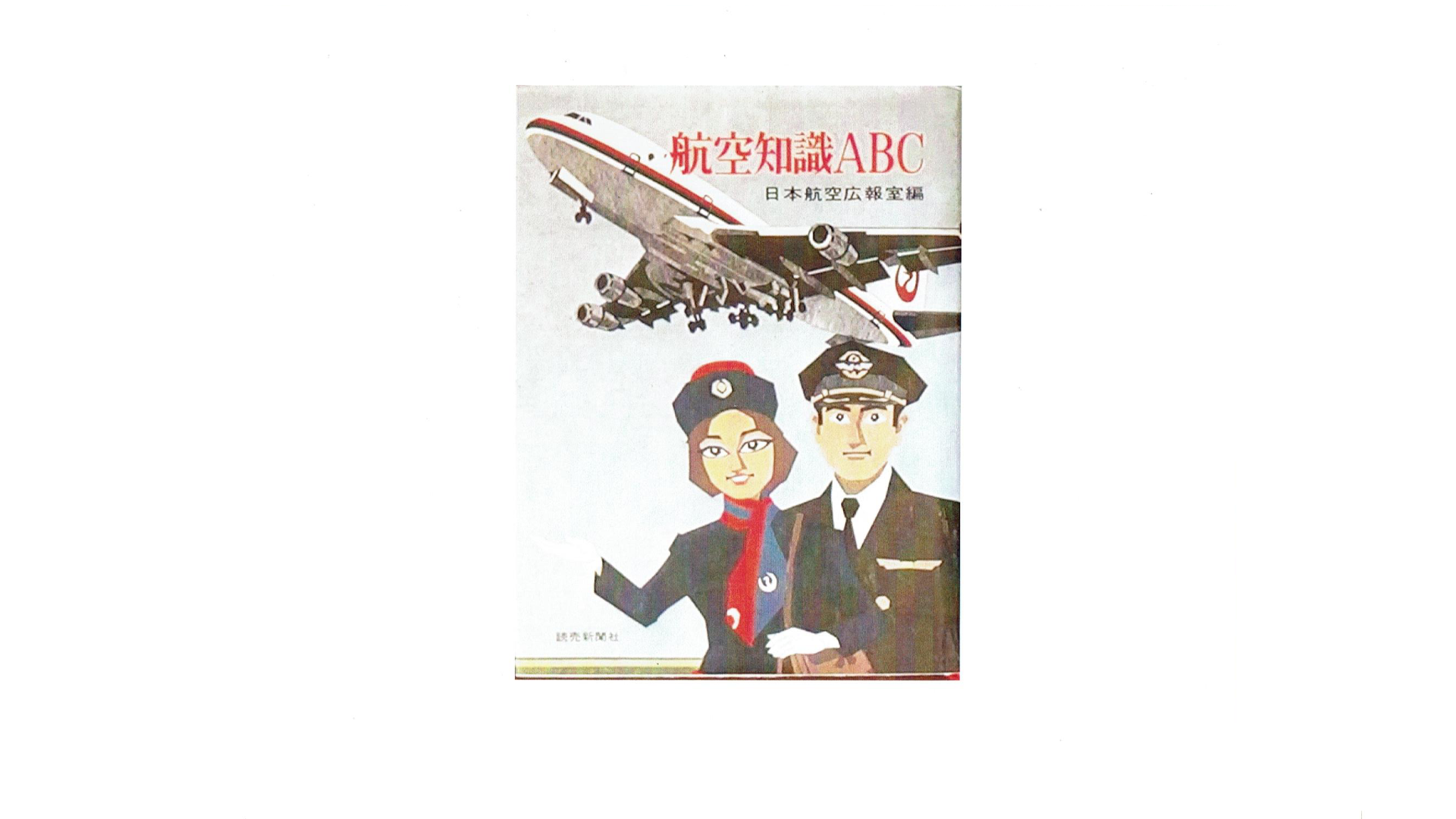

The process of air outflow caused by a 2-square-meter tear in the pressure bulkhead cannot stop the continuity of the air outflow, and after a few seconds the cabin becomes equal to the outside air pressure.

This is what JAL admits in its book "Aviation Knowledge ABC". Even in this respect, the accident investigation report has fallen into a logical failure.

People were able to breathe for 32 minutes from time zero, stay conscious and admit the suicide note.

A man in the backseat on the flight just before Flight 123 heard an eerie squeak from the attic, which was unusual during the flight.

Shouldn't the accident be fundamentally re-examined in light of these situations, which are different from what is stated in the report?

I hope the Japan Transport Safety Board has the courage to become a sensible group of engineers.

I would like to note the investigation into the crash of ANA B727 off Tokyo Bay Haneda, which caused the largest number of casualties in the single aircraft accident at that time in February 1966.

In this accident, the views were divided into two and conflicted. There was a maneuvering error theory and an aircraft defect theory. After all, four years later, a mysterious report that the cause was unknown was published.

Masao Yamana, who was involved in the investigation as a member of the accident investigation team, said in front of a huge number of debris.

Yamana says, "For those who do not have the habit of looking at the real thing and making judgments, it is like talking to people who are not interested in painting, and it seems impossible to expect understanding."

Yamana resigned from the accident investigation committee with the pride of the engineer, and asked the world about the results of his own attempt to clarify the truth and prove it.

There was a similar situation in which the committee members quit in the accident at Mt. Osutaka. At the same time, the conclusion was summarized without seeing the wreckage that sinks in Sagami Bay mentioned above.

The current situation in Japan is that the two accidents that recorded the largest in the world are officially recorded in an ambiguous situation in terms of their causes.

This situation should be called anomalous. There is no point in being suspected of trying to settle the site politically with the law as a shield.

Not a few people, including myself, point out the irrationality of the report. Now, the facts that can be considered objectively have been revealed. I sincerely hope that the Japan Transport Safety Board will show the courage to return to the starting point.

And I want them to appreciate the pictures drawn here, and I believe that the pictures will tell the truth.

Five years ago, when I applied for a short story from a newspaper company with the theme of "Let's walk upwards" and won the highest award, Kyu Sakamoto, who sang the song, asked me to clarify the truth. I remember feeling strange as if I was pressed.

In the summer of the 35th year, I heard "Let's walk upward" recorded on the IC recorder I carried at Mt. Osutaka.

That summer night, some people must have spent the night alone on Mt. Osutaka, counting the bleeding stars.

At the foot of the mountain, the village fire brigade, the hunting club, the police, and the Self-Defense Forces all worked hard all night to reach the crash site as soon as possible.

It was a really sad and unfortunate accident.

The worry is that if the memory goes beyond oblivion, one may encounter the same accident again. Because proposals and recommendations for untrue accident causes are unclear in effect on the truth.

I have posted my record on YouTube seven times since August 2021. Hoping to help those who will lead the next era and challenge the truth, I will report to the Spirit of 520 again "Wings of Silence."

My other channel, "Airplane Yomoyama Story," will be posted irregularly, but you may come across JA8119. Thank you for watching this as well.

Thank you for watching "Wings of Silence".

This was reported by Takahiro Jikuen, an aviation history researcher.